Metal

The manufacturing companies in each industry have their own development story. For example, the tradition of metalworking began in the middle of the 19th century along with the construction of Liepaja lighthouse, which was definitely continued by Bekers un co, which later turned into the flagship of Liepaja industry – Liepājas Metalurgs. Currently, there are a number of Scandinavian metalworking companies that successfully work and export their products, such as Trelleborg Wheel Systems Liepaja which manufactures tractor wheel discs, Lesjofors which produces various types of springs, Caljan which is the creator of telescopic conveyors for mail stations, Jensen Metal which produces equipment for the food industry.

Lesjofors facts

Lesjofors Springs LV LSEZ SIA

Year of founding: 2003

Employees: 95

Turnover: 6 Million euro

Lesjofors Gas Springs LV LSEZ SIA

Year of founding: 2008

Employees: 60

Turnover: 3.3 Million euro

Springs from Liepāja, Even for Lamborghini

The company Lesjofors Springs LV manufactures springs for goods used by each of us, as well as for well-known worldwide brands such as McDonald’s, Husqvarna, Stihl and even Lamborghini.

The company production plant in Latvia, Liepāja has been engaged in the production of springs, gas charged shock absorbers and stamped parts since 2003, as well as it distributes the products manufactured by Lesjofors Group. Liepāja was chosen as the only place for the plant in the Baltics, which attracted investors both in terms of the premises required for the plant and due to the fact that Liepāja has historically been known as an industrial city with a strong metalworking industry. Currently, the company has grown to such a level that at the beginning of April it moved into new premises of 11 000 square metres, into the construction of which Lesjofors invested around 6 million euros.

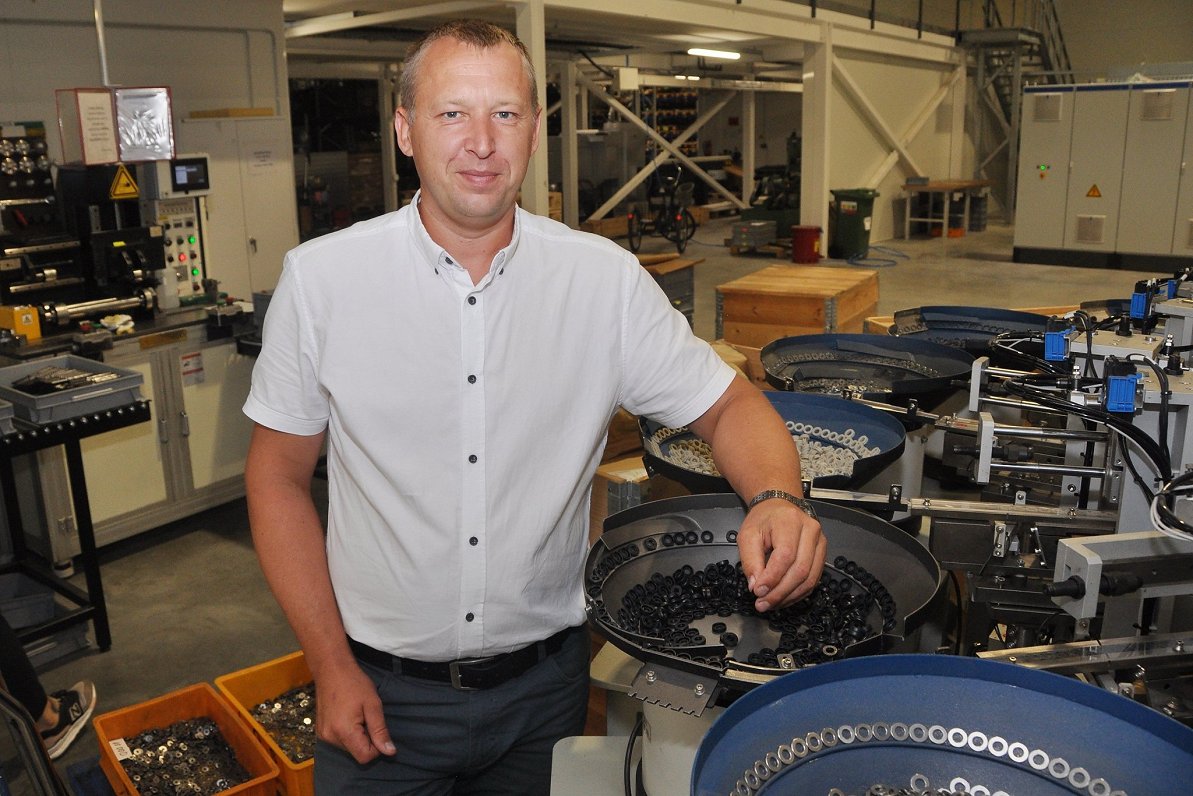

Springs for all cars

The products manufactured by Lesjofors are small components – stamped or spring parts, which are produced in large batches of thousands of pieces. “We do not produce any finished parts, therefore all the products that we make are just components of another product in the making. They are meant for manufacturers who operate in various industries and who require springs or stamped products,” says Ingars Jaunzems, Director of LSEZ SIA Lesjofors Springs LV.

The products produced by Lesjofors reach representatives of various sectors, such as electronics, medicine, automobile engineering, telecommunications. Lesjofors manufactures springs for all car models in the world, focusing especially on those found in, for example, car lamps, seats, engines. In general the company does not produce chassis springs, with the exception of the Lamborghini order. The company’s customers also include well-known brands such as McDonald’s, Husqvarna, Stihl.

“Everyone of us most surely use something produced by Lesjofors, for example, on the phone or TV. It is just that no one really knows where these parts are manufactured,” reveals Jaunzems.

For each of the product types Lesjofors Springs LV has approximately 2000 article numbers, which are updated annually.

Unique in Europe

Lesjofors currently operates about 30 factories around the world and Liepāja is the only factory in the Baltic states. The Liepāja plant is slightly unique in Europe. It produces two products that are certainly not produced anywhere else in Europe: gas springs and power springs. Elsewhere they are only produced in the USA, while gas springs – only in Korea. Lesjofors Springs LV mainly focuses on the Scandinavian market due to its convenient logistics, but products are also delivered to, for example, Mexico, China, India and elsewhere.

“I think that Liepāja is a very good place for the development and planning of production, as the city is industrial. Although we are located by the sea, there have always been factories that produce something here. Also, the support provided by Liepaja Special Economic Zone is a big motivating factor, because by investing in equipment and modernising the factory, it is possible to recover taxes. It motivates, and drives us forward to invest,” says Jaunzems.

Textiles

Along with the construction of the textile company Lauma in the 1970s in Liepaja, light industry declared its strong positions here, and it was also able to switch and adapt to market conditions after the collapse of the Soviet Union. The spacious premises of Lauma can also be called an industrial park, as a number of other companies that produce medical patches, geotextiles for road construction, and medical bandages, as well as others have found their home there.

Patches for Every Occasion

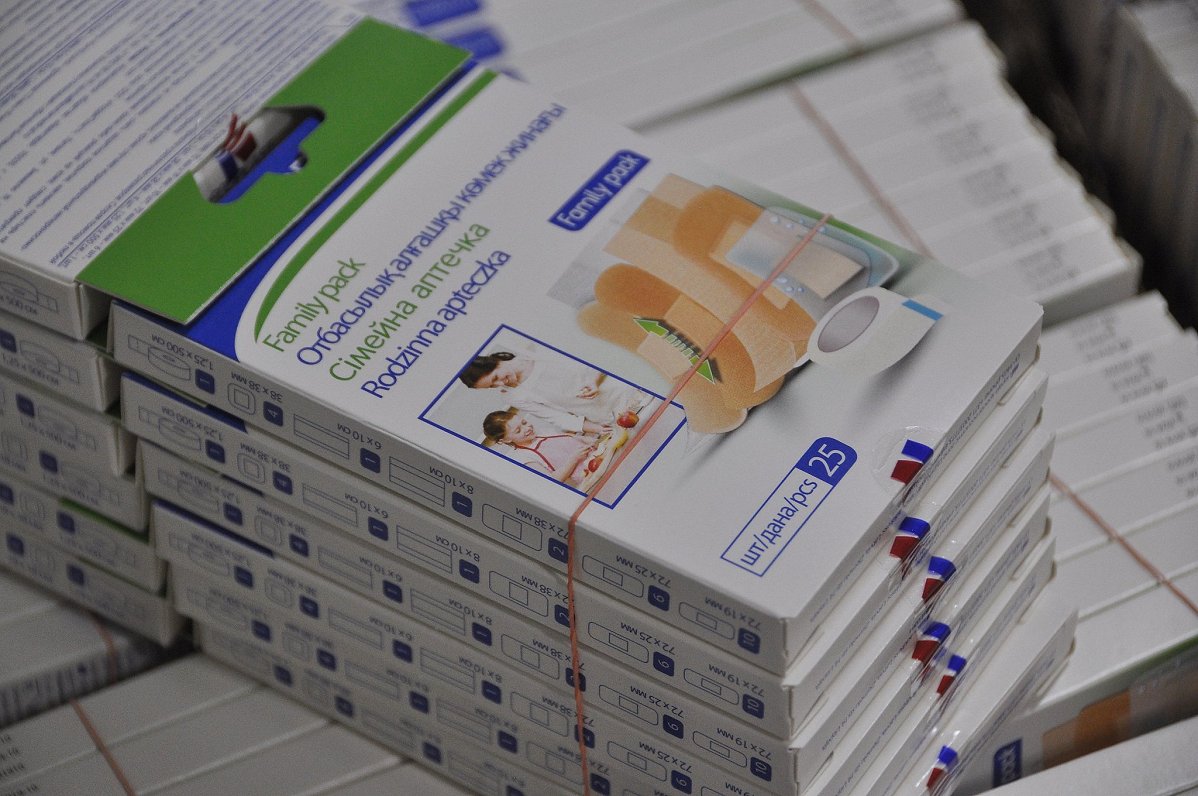

LSEZ SIA NordePlast began its operation in 2016, but the first production batch was sold at the beginning of 2017. Although the company is relatively new and small, this does not prevent it from competing with large and well-known foreign manufacturers of patches. Currently, the company produces about 100 different types of patches and 90% of them are exported to Ukraine, Poland, Belarus, as well as in small quantities to Russia and Georgia. However, the company has also begun to develop actively in the Baltic states – starting with Latvia and moving to Estonia and Lithuania at the same time.

“The competition is very high. In Latvia we are the only ones who produce patches, but we have to compete with big foreign brands, such as Compeed, Urgo, which have been operating in this market for a long time. They are widely represented in stores, as well as pharmacy chains. There are also many small distributors representing the Chinese manufacturers,” says Romāns Gramiko, Member of LSEZ SIA NordePlast Board.

NordePlast facts

LSEZ SIA NordePlast

Location: Liepaja (Latvia)

Turnover: 141 232 euros (in 2019) 207 991 euros (in 2020 until the end of June)

Number of employees: 12

Year of founding: 2016

The company offers various product lines for different needs, such as wart remover patches or blister patches and others. “Sometimes the consumers are not aware themselves of what patches they require. Our goal is to keep up with the news in the world market, the innovations, the changes in materials and technologies. We also follow the competitors, in order not to lag behind and to move forward in the same step. Our products have to be modern, attractive and the consumers must be aware that there are many types of patches. You can find a solution to every problem,” explains Gramiko.

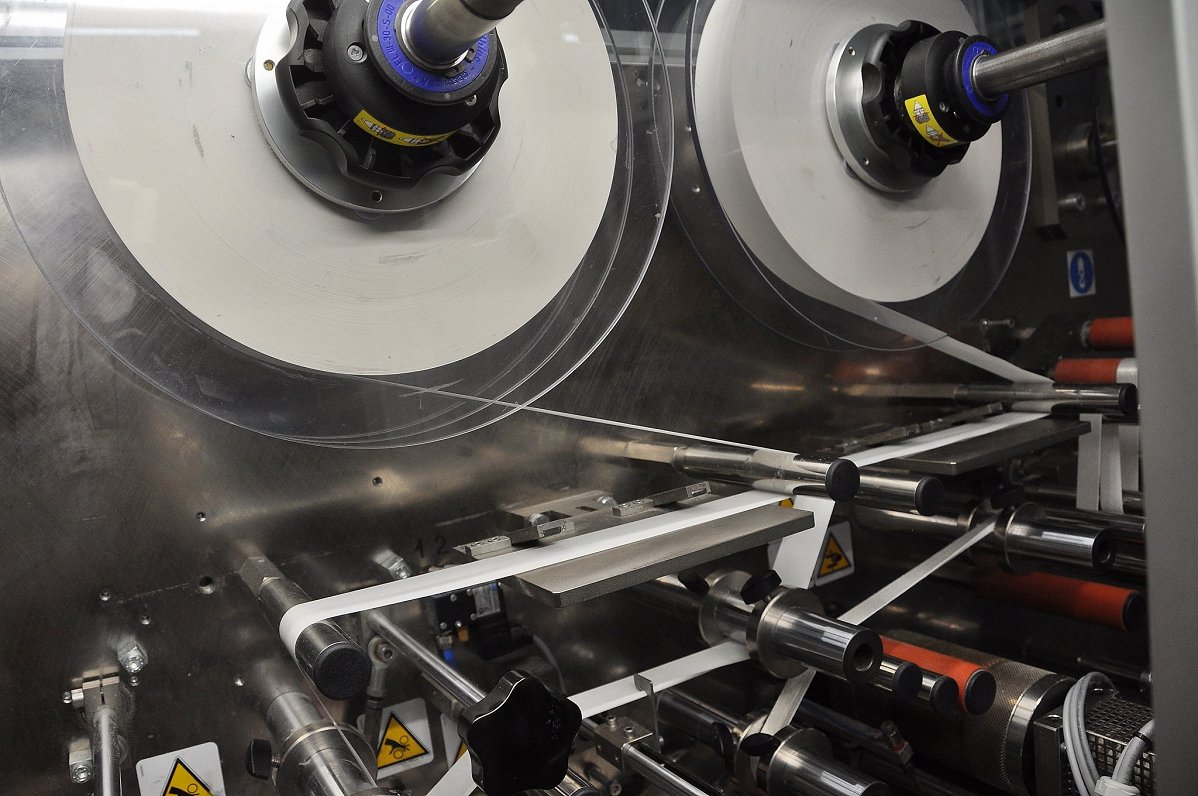

2,000 patches per minute

Quite recently, the company expanded its production plant and received new equipment, which allows it to double its production capacity. So far it has been possible to produce 2000 patches per minute. One of the main goals of the company is to sign agreements with local pharmacy networks. The company is also ready to cooperate and produce patches for private brands.

“Our plans to develop and grow are huge. The next product we would like to implement is sterilised products that are suitable for hospitals. When the certification is received, these products will be available throughout Europe,” reveals Gramiko. The company plans to continue its development in Liepāja and praises the fact that Liepāja has a great geographical location – in the middle of Europe, the port is located next to it, and cargo transit is convenient here. Great support is also provided by the municipality.

Technology

In recent years, technological companies have announced their operation, which develop modern technological solutions and products themselves – electric karts, industrial drones, 360-degree robotic cameras, etc. For example, the engineering company of equipment assembly LSEZSIA EURO DK was founded in 2007, and currently exports its production to more than 150 countries.

About 62% of the equipment is exported to Europe, and the rest to other countries, such as Asia, Africa, Saudi Arabia. Starting from 2009, the company successfully produces various equipment for wired and wireless network installations: routers, antennas, network switches, cables, security and monitoring tools. The company range includes about 1300 items from the leaders of the network goods industry, such as Ubiquiti Networks, Mikrotik, Teltonika, Cambium Networks and others.

EURO DK not only cooperates with manufacturers of equipment, but also with Amazon, Ebay and other trading platforms. In 2016, the company received the status of a Liepaja Special Economic Zone company. In turn, in 2018 the company completed the construction of a new office and warehouse building in Liepaja and plans to expand in the future.

You can read more about the German-Baltic Chamber of Commerce in Estonia, Latvia and Lithuania at the official website and find out more about the Baltic Business Quarterly magazine here: https://www.ahk-balt.org/lv/publikacijas/zurnals.