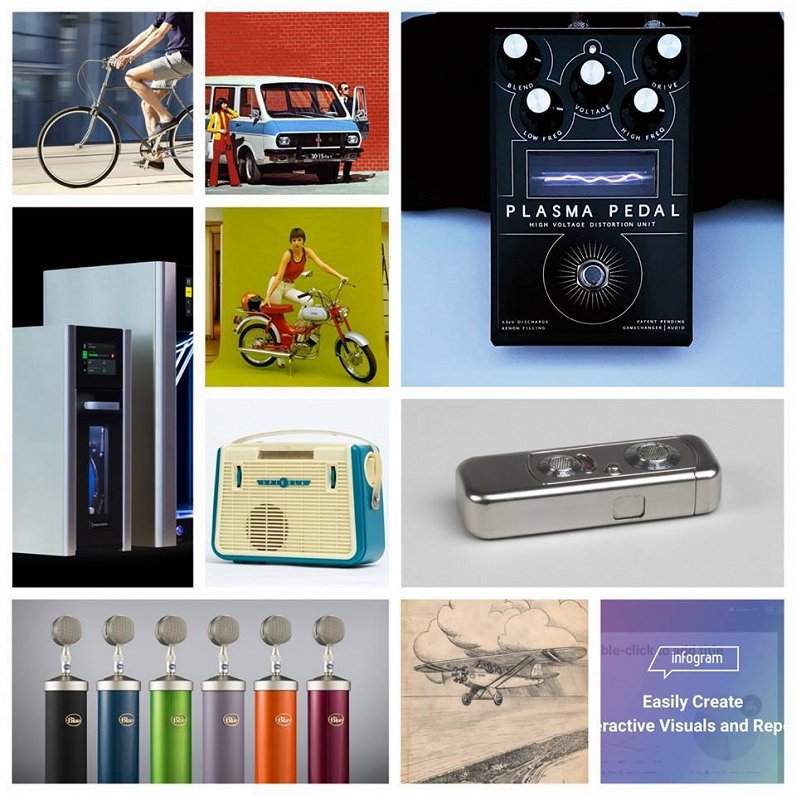

Today, design – meaning the purposeful development of user-oriented solutions – is an integral part of innovation. Design is what makes technically complicated ideas accessible, attractive, and easy to use; design is a springboard for start-up products and the development of globally important services. This advantage is not relevant to the current century alone – internationally competitive solutions were unimaginable without clever design at the time when inventors, artists-constructors, or other related professionals were responsible for design. For instance, had Walter Zapp had the opportunity to participate in a start-up accelerator in 1936, VEF Minox would have definitely received large investments. The world’s smallest photo camera of its time is an excellent example of world-class made-in-Latvia product design, and it is not the only example. I have collected ten sustainable, innovative, and commercially successful Latvian product design achievements of Latvian and global importance over the last hundred years.

The World’s Smallest Photo Camera, The VEF Minox

The VEF Minox, the world’s smallest photo camera, is Latvia’s most popular and commercially successful design solution on an international scale, and the only one to be exhibited in the New York Museum of Modern Art (MoMA) so far. The camera is included in the Latvian Cultural Canon list of 99 most valuable items, but, to be fair, it is necessary to explain that the gadget’s creator Walter Zapp is a Rīga-born Baltic German who invented the miniature camera while living in Estonia. The Zapp family went into exile to the West during World War I, but finally settled down in Tallinn. The talented autodidact Zapp started his apprenticeship in a photo studio there in the 1920s and developed an idea of a small, easy to use camera whose technical parameters would nevertheless be on par with other contemporary photo cameras. The first functional Minox prototype was created in 1936.

After an unsuccessful attempt to launch production in Tallinn, Walter Zapp and his business partner Richard Jürgens signed a contract with the State Electrotechnical Factory (Valsts elektrotehniskā fabrika, VEF) director Teodors Vītols, who decided to start the production of the subminiature photo camera in Riga despite the fact that the factory had never worked on precision mechanics projects before. Walter Zapp returned to his hometown, where he adapted the world’s smallest fully functional photo camera for industrial manufacture in a very short time – 18 months. Its size was not the only innovative aspect. Its mechanism – the double film cassette and telescopic chassis – was also a novelty of its time, patented by VEF in 22 countries in the world. Manufacture started in 1938, and 17,000 VEF Minox cameras were made until World War II with the inscription “Made in Latvia”. Each camera was manufactured and assembled in Riga; only the optic glass and photographic film were imported from Germany. The camera was 17 x 27 x 70 mm, weighed 125 grams, and cost 248 lats. In addition, camera owners could buy an elegant VEF Minox accessory set – two enlargers, a film developing tank for use outside the darkroom, an adapter for the developing postcard-size photos, a light meter, the head of a film stand, a loupe for viewing the negatives, envelopes for the developed film, and a storage box for two rolls of Minox film.

Production of Minox in Riga ceased in 1942 and did not start again. Production equipment was brought to Germany during the war, where Minox GmbH, founded by Walter Zapp, continued the production of miniature cameras until 2012.

VEF Aircraft

The idea of industrial manufactured aircraft at the State Electrotechnical Factory was conceived in 1935 by the legendary aviation engineer Kārlis Irbīte. VEF director Teodors Vītols supported Irbītis’ idea, because, at the time, the factory-owned subcontractor Latvijas Bērzs (“Latvian Birch”) was not only producing plywood for VEF radio, but also quality material for aviation equipment finish, with large quantities exported to war-haunted Europe and constituting a significant part of VEF’s earnings. Irbītis’ first plane, the I-11, was designed in 1936 and served as the basic prototype for the aircraft that followed. The destroyer I-12 received the honorary diploma of the International Aircraft Exhibition in Paris and first prize in the King Cup Race competition in the category of two-man aircraft the following year. Its international debut in France was followed by successful participation in exhibitions in Great Britain, Germany, and other countries. In July, 1938, pilot Philip Avery flew from London to Riga in 9 hours and 5 minutes without landing, breaking Bert Hinkler’s previous record by an hour and 40 minutes.

VEF built twelve I-12 aircraft until the outbreak of the Second World War. Over the following years, several other models were built, but the light destroyer I-16 earned the most esteem. Development started in 1939, and it was planned that it would gradually replace imported planes in Latvia. A separate hangar was designated for the construction of the destroyer, and a VEF plane factory was going to be built in Ropaži. These plans fell through because of the war, and I-17 turned out to be Kālis Irbītis’ last aircraft to be entirely constructed at VEF.

Ērenpreiss Then and Now

Looking back at the history of bicycle production, 1880s Latvia marks the spot where the first bicycle in Tsarist Russia was created. Alexander Leutner’s pioneering bicycle workshop was one of the first bicycle factories in the territory of Latvia, soon to be followed by several others. Bicycle production in Latvia plummeted during the First World War, but it rapidly restored when the country gained independence. In their book From Leutner to Erenpreiss, authors Edvīns Liepiņš and Jānis Seregins note that, by the mid-30s, virtually no bicycles were imported since local bicycle manufacturers could completely provide the necessary supply. There were 299,300 bicycles in use in Latvia in early 1941, 42,059 of them in Riga. Since the early 30s, the number of bicycles in Riga had grown quicker than the population. Post-war estimates forecast that the number of cyclists in Riga would grow fivefold by the 90s, and experts suggested a reconsideration of the city’s development plans.

G. Ērenpreiss’ Bicycle Factory was the most productive bicycle manufacturer in the interwar period. The factory started operations in 1927, it was proclaimed the largest and most modern bicycle producer in the Baltics in 1940. The factory produced 70% of all the bicycles bought in Latvia, yielding 40,000 bikes per year. The volume of output increased to 200,000 bicycles by early 1940, and the top-notch Ērenpreiss bicycles were sold not only throughout Latvia, but also in Estonia, Finland, Poland, and the Soviet Union. When the USSR occupied Latvia, the Ērenpreiss factory was nationalised and renamed the Red Star State Bicycle Factory. Bicycle production was stopped during the war, and it restarted in the late 40s. The factory shifted to motor vehicle production a decade later, and it took almost half a century until the great grandson of Gustavs Ērenpreiss’ brother restarted Latvian bicycle production by overtaking the brand. Toms Ērenpreiss opened a bicycle restoration workshop in 2006, and the production of four new Ērenpreiss bicycles was started in 2012. The company currently offers six types of bicycles for sale.

The Red Star Mopeds

The production of motor vehicles in Latvia started along with the bicycle industry: the first motorcycle in the Russian Empire, and the first motor vehicle on three wheels, a tricycle, was produced in 1899. Motorcycles were not produced in Latvia after the First World War, and the production of motor vehicles resumed only in the late 50s. Early experiments in motor vehicle production in post-war Latvia took place in the former Ērenpreiss workshop, then known as The Red Star: the Rīga 18 bicycle was fitted with a two-stroke D-4 bicycle engine. The bicycle had a single horsepower and could obtain a speed of 35 km/h. The motorised bicycle Gauja was created in 1961 with a slightly modified construction, based on the initial prototype.

Mopeds and motorcycles gradually replaced motorised bicycles in The Red Star factory. The Rīga moped series was particularly popular. Rīga 1 was created in 1960, followed by Rīga 3 (1965), the basic model Rīga 4 (1970) and several particularly sought-after types – models Rīga 12 (1973), Rīga 16 (1978) and Rīga 22 (1981), created by designer Gunārs Glūdiņš. The moped Rīga 12 is included in the Latvian Cultural Canon as a paragon of Latvian industrial design. The Red Star was one of the leading producers of motor vehicles in the territory of the former Soviet Union in the late 60s, with yearly production capacity of 113,000 mopeds, 59,000 mokicks, and 16,000 minimokicks. The output of mopeds and sports motorcycles continued to grow in the 80s; Delta, Stella, and other new models were released. The Red Star vehicles were sold not only all across the Soviet Union, but also in Vietnam and Cuba. The production of motor vehicles in Latvia continued until 1998.

VEF Radio

In March, 1925, an experimental radio transmission took place with the words “Hello, hello, Rīga radio testing!”, and the Rīga radiophone was launched in autumn of the same year. The radio gained gradual popularity in Latvia, with increasing demand for quality radio receivers that would allow the transmission of both local and international radio broadcasts. The first radio sets in Latvia were produced by the Post and Telegraph Head Authority Main Workshop, which was renamed the Pērkons (“Thunder”) workshop, then rebranded again as the State Electrotechnical Factory (Valsts elektrotehniskā fabrika, VEF) in 1932. VEF produced an extensive range of items in the 1930s, inspiring the saying: “VEF produces everything – from needles to planes”; however, radio was invariably one of the most sought-after product types were manufactured both for the local and the export markets. 75 different types of radio sets were developed under Kārlis Irbītis and Alberts Madisons’ leadership from 1933 to 1941. These received positive distinction in international exhibitions, and 8,000 sets were exported annually to Finland, Norway, Sweden, Estonia, Lithuania, and other countries.

Artist Ādolfs Irbītis, Kārlis Irbītis’ youngest brother, was appointed the head artist of the VEF artistic construction department after the Soviet occupation. The former production of a wide range of products was narrowed down to two priorities – radio and telephone equipment. The VEF team started a concerted effort to decrease the size of radio receivers in the late 40s. Irbītis’ Tourist (1955) enjoyed wide popularity – a compact radio receiver, mimicking the shape of a woman’s handbag, with bright plastic – a material still uncommon in Soviet manufacture – replacing the plywood. It was the first portable radio receiver in the Soviet Union. The first transistor receiver, the Spīdola, supplemented the innovative range of radio equipment in 1960, augmented several times over the following years. The Spīdola radio set was popular both within, both beyond the Soviet Union. All VEF radio receivers in the 1960s and 1970s were developed on the basis of this model.

The RAF-2203 Latvija Minibus

The RAF Latvija minibus, constructed and produced in Latvia, was the first small-size bus in the territory of the Soviet Union, and remained the most popular one for many years. The first minibus models in the Riga Bus Factory (Rīgas autobusu fabrika, RAF) were created in the late 50s, and the experimental RAF-10 Festival and RAF-08 Sprīdītis, as well as minibus RAF-977 Latvija, adapted to mass production, were all available for sale within and outside of the Soviet Union.

A new factory in Jelgava city was opened in the 70s, and a new basic model was added – RAF-2203. The ultramodern minibus looked different than the existing RAF designs, largely interpreting the sculpture-like appearance of the Volkswagen Transporter – the new vehicle, dubbed “little RAF” by Soviet citizens, was a dynamic wagon-type vehicle with eleven seats. The minibus body could be adapted to serve various functions – the minibus was widely used for city minibus routes, ambulances and police vehicles. The model could be modified for cargo transport, and small quantities of minibuses with “luxury” interior design were offered for sale to private individuals in the late 80s as a part of a support programme for large families. Among the most ambitious variations of RAF-2203 Latvija were the experimental electro mobiles designed for the needs of the 1980 Olympics – RAF-2207 and RAF-2910. The electromobile could ride for up to 100 km with a single charge, but the maximum speed did not exceed 30 km/h. This car was mostly used for the maintenance of the marathon race in the Olympic Games, because it was quiet and did not produce harmful emissions. Another electromobile, the RAF 2210, was developed after the Olympics – it was used as a city minibus. It could drive up to 70 km with a single charge with maximum speed of 65 km/h.

BLUE Microphones

Studio microphone company BLUE Microphones was established by Latvian sound engineer Mārtiņš Saulespurēns, and, for over 20 years, the company has been producing award-winning sound equipment, used by world-famous musicians such as Madonna, Sting, Pink, Norah Jones, and others. Mārtiņš Saulespurēns, the founder of BLUE Microphones, grew up in a family of professional musicians, studied engineering and spent over twenty years working in the Latvian Academy of Music and restoring microphones. In the mid-90s, he met the musician Skipper Wise and together they established the company BLUE Microphones (BLUE – Baltic Latvian Universal Electronics) in the US. The founders were initially planning to produce high-quality hand-made microphones for their musician friends, but the first microphone Bottle rapidly attracted interest in the beautiful, high-quality BLUE audio equipment. The Bottle microphone resembled 30s audio devices, having outstanding technical quality and casing in bright colours.

In contrast with most solutions available in the market, the names of BLUE microphones are not combinations of anonymous letters and digits, but purposefully chosen catchy and memorable names and similes to highlight the unique nature of the microphones. The most well-known BLUE microphone projects of the current millennium are Spark Digital – the first microphone to combine USB and iOS compatibility, and Yeti microphone – the BLUE product with the highest number of sales, the most popular USB microphone in the world, and the first TXH (Tomlinson Holman’s crossover) certified microphone. The Ball microphone series is also well-known and much enjoyed, including the Ball, Eightball, Kickball, and Snowball microphones.

Unfortunately, despite the successful operations of the founders, BLUE Microphones relation to the Baltic region, as encoded in the company name, remains only historical – founders Mārtiņš Saulespurēns and Skipper Wise, unable to satisfy the increasingly growing demand, sold the company ten years ago. The duo continues to work in their new company Neat Microphones.

Mass Portal Printers

Mass Portal, operating since 2013, is the only company in the Baltics that produces 3D printing equipment. Mass Portal differs from other printers on the market with its fast performance, precision, low level of vibration and noise, and an intuitive, well thought-out visual design and interface. The number of Mass Portal products has significantly increased over the five years of development, and the producer highlights the MoNaDe (Modular Natural Design) concept as a significant quality indicator, which means ‘introducing unified design principles in the entire product line, from desktop to mass production, based on convenient use, performance capacity, clean materials and production technology’. The MoNaDe principle also appears in the convenient interface design, which, like the material components of the product, has been fully developed in Latvia: previous skills are not necessary to use Mass Portal printers. This year, Mass Portal FD1, world’s first professional 3D printing material drier for standard 3D printers, was introduced to the Mass Portal product range. The drier was created to make the printing material more durable and the print itself more precise.

The Infogram Data Visualisation Tool

The Infogram data visualisation tool is a next generation design solution created and developed in Latvia for solving global problems – to present complicated data conveniently, quickly, and effectively. It is a SaaS (software as a service) type product, where the user creates interactive data visualisations, information panels, and other visual structures online. The data visualisation tool is used by almost 4 million people worldwide, but the content created with Infogram is viewed 61.85 million times per month. Las year, because of its international success, Infogram received the first National Design Award of Latvia 2017, highlighting the role of non-material design and development potential in Latvian design.

Infogram is an excellent representation of how the new generation of designers think – the solution is developed concentrating on user-oriented design both in product development, both in the company’s operations altogether. The data visualisation tool is in constant development – the developers analyse the users’ needs, perform testing, and gradually improve the functionality of the product. Such user-oriented, data-based design development approach allows a broader look at the field in Latvia, too. From traditional products, which are often local and oriented towards the individual and his consumption habits, 21st-century design has developed into a global, inter-disciplinary instrument of societal importance for solving social problems.

Guitar Pedals that Transform Music

The innovative company Gamechanger Audio has achieved remarkable success over a couple of years – Latvia-made guitar pedals are known among professional musicians all over the world. The first Gamechanger Audio product, the Plus Pedal piano type guitar pedal, was developed in 2017, and it differs from other audio effect devices with its unusual visual appearance as well as the fact that it represents a brand new type of audio effects – the sustain effect. The sound synthesising algorithm was fully developed by the authors. This year’s invention, Plasma Pedal, is the first pedal with an overdrive effect, which, instead of modifying sound with LED circuits, transistors or vacuum tubes, generates the effect with gas discharge in xenon tubes. Electric discharges are transformed into an analogue audio signal, creating a rapid, very powerful sound deformation, audible to musicians during performance.